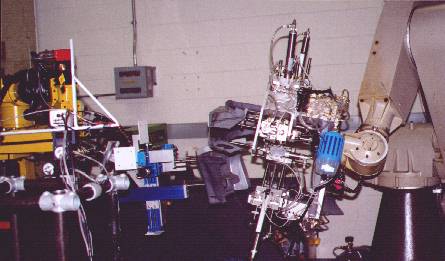

Robotic Fixtureless Assembly

-

Grasp planning strategies for accurately and rigidly locating parts.

-

Multi-degree-of-freedom servo grippers capable of handling a large range of part sizes and shapes

-

On-line 3D pose measurement and correction (using 3D machine vision).

-

Correction of initial part placement errors using 2D machine vision.

-

Vibration control for high speed motion of flexible payloads.

Description

Fixtures (also known as "hard tooling") are used in industry to align and hold parts for joining operations. These fixtures are part specific and must be changed whenever the product is changed. This process, known as "re-tooling", is very expensive and time consuming. With robotic fixtureless assembly (RFA) the fixtures are replaced with sensor-guided robots equipped with programmable grippers. We have developed an RFA workcell that has been tested using a four component automotive sub-assembly. This workcell involves several technical advances:

During the robotic fixtureless assembly of a four component sub-assembly

Researchers

Dr. Gary Bone, Dr. David Capson, Jay Stavnitzky, Lucian Balan, Michael Colella, Derek Matthews, William Plut, Robert van Varseveld, Thomas Vermeltfoort and Timber Yuen.For Further Information Please Contact: