Multiple Degree-of-Freedom Robotic Servo Grippers (Patented)

Description

In

several industries, including automotive, aircraft, camera and photocopier

manufacturing, a large number of complex shaped 3D sheet metal (and sheet

plastic) parts are joined to make frames and bodies. A robotic gripper

suitable for this task has four requirements:

- i) part pickup

-

ii) rigid part locating,

iii) accurate part locating, and

iv) ability to grasp a wide range of shapes.

We

have developed three robotic servo grippers that meet these requirements

and can grasp a wide variety of parts. The grippers feature a novel finger

design that allows them to accurately and rigidly locate the parts in

the presence of initial robot and part positioning errors. Tests have

been performed with gripper prototypes on several automotive parts. The

standard deviation of the parts position was reduced to 0.05 mm after

grasping, from 0.4 mm prior to grasping. For more details please see our

video and

publication pages. For details on the application of these

grippers to automotive assembly please see our fixtureless

assembly page.

-

Examples of parts that can be grasped.

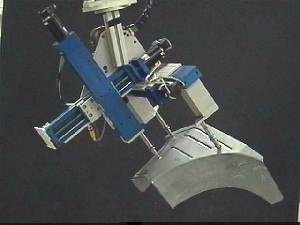

First generation gripper (2 servo controlled axes) holding a part.

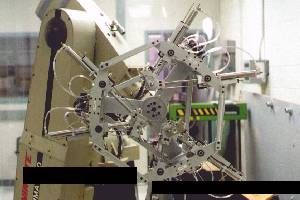

Second generation gripper with a 400 mm workspace and 9 servo controlled axes.

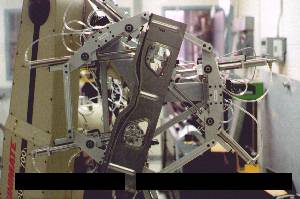

Second generation gripper holding a part.

Third generation gripper with a 200 mm workspace and 4 servo controlled axes.

Third generation gripper holding a part.

For Further Information Please Contact:

Dr. Gary M. Bone

Dept. of Mechanical Engineering

McMaster University

Hamilton, Ontario, CANADA, L8S 4L7.

Phone: (905) 525-9140 ext 27591

Fax: (905) 572-7944

e-mail: gary at mcmaster.ca

Researchers

Dr. Gary Bone, William Plut, Robert van Varseveld, Lucian Balan.